Press Release

View printer-friendly version

Kipling Gives Away Materialise’s 3D Printed Bags

Leuven, Belgium – March 14th, 2014. Belgian bags and accessories brand Kipling has partnered with Materialise to co-create the "City Jungle Shopper" and will be giving away these 3D printed bags in a contest running from today until April 2nd, 2014. Based on the Monkey Madness collection, this bag showcases its monkey mascot role in the world's first fully-flexible 3D Printing material TPU 92A-1.

From 2D to 3D

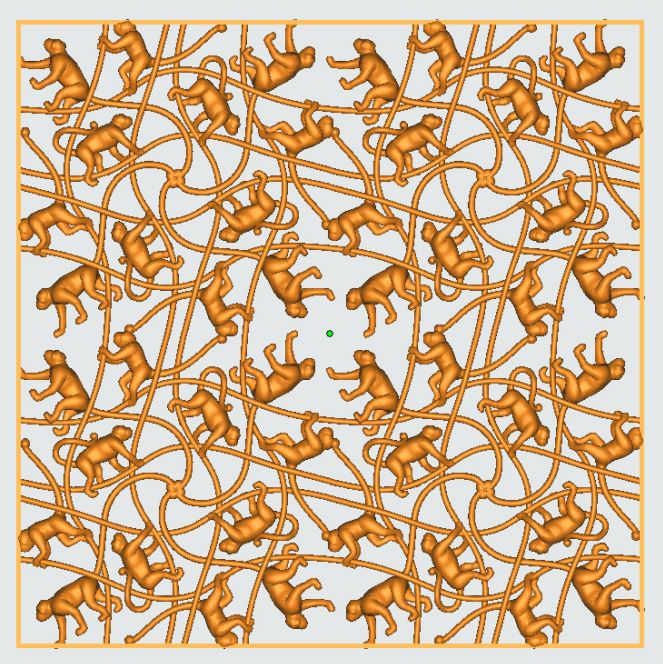

The idea consisted of creating a 3D printed plastic bag starting from the Monkey Madness collection, which is based on different designs of the Kipling monkey. Materialise engineers started by converting the 2D monkey silhouettes into 3D shapes and designed 4 different 3D patterns in the 3-matic software. The customer chose one out of these 4 prototyped patterns. Speaking about the partnership, Jürgen Derycke, Kipling's Media – PR & Digital Marketing Manager said, "Materialise really took us to another dimension with these monkey bags through their 3D Printing technology. We are always looking for innovative approaches for our bags, and we are very happy with our new City Jungle Shopper bag. We hope to work again with Materialise to create more state-of-the-art products!"

Speaking about the partnership, Jürgen Derycke, Kipling's Media – PR & Digital Marketing Manager said, "Materialise really took us to another dimension with these monkey bags through their 3D Printing technology. We are always looking for innovative approaches for our bags, and we are very happy with our new City Jungle Shopper bag. We hope to work again with Materialise to create more state-of-the-art products!"

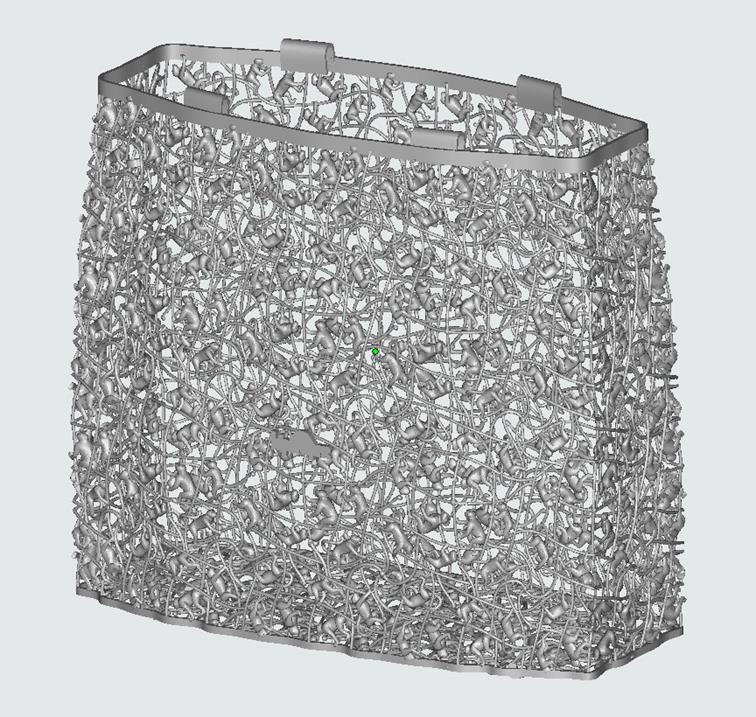

Kipling and Materialise decided on a structure with the monkey's tails touching to create a pinwheel effect in the pattern. Once the right pattern  had been chosen, bottom and top rims were added to the design for overall stability. Hooks on the top rim ensured later attachment of shoulder straps. The final piece was printed in 1 piece.

had been chosen, bottom and top rims were added to the design for overall stability. Hooks on the top rim ensured later attachment of shoulder straps. The final piece was printed in 1 piece.

Materialise printed two types of bags in two distinct materials: one is made in Materialise's latest fully-flexible material, TPU 92A-1 using laser sintering technology and the other one is made with more traditional epoxy material using Materialise's Mammoth Stereolithography technology.

This project demonstrates Materialise's extended expertise in the entire process of 3D printing, from design and engineering all the way to the printing and finishing.

Click here to enter to win this bag between March 14, 2014 and April 2, 2014.

For more information, please contact:

Vanessa Palsenbarg

Corporate Communications Specialist, Materialise

Phone: +32 16 39 66 37 +32 16 39 66 37

+32 16 39 66 37

Fax: +32 16 39 66 00

Email: Vanessa.Palsenbarg@materialise.be

Twitter: @belgiancanuck or @MaterialiseNV

Visit: www.materialise.com

About Materialise

With its headquarters in Leuven, Belgium, and branches worldwide, Materialise has been playing an active role in the field of Additive Manufacturing (AM) since 1990. In addition to having the largest capacity of AM equipment in Europe, Materialise also enjoys a stellar reputation as a provider of innovative software solutions. They have used their experience and expertise to create a better and healthier world through their involvement in AM for industrial and medical applications, and by providing bio-medical and clinical solutions such as medical image processing and surgical simulations. Materialise has developed unique solutions that make a world of difference for its many customers with their prototyping, production, and medical needs. These customers range from large companies in the automotive, consumer electronics, and consumables sectors; to famous hospitals, research institutes, and clinicians; to individual consumers interested in bringing their own unique creations to life through i.materialise or who want to purchase a celebrated .MGX design.